Subscribe to ARB

Subscribe to ARB to receive your regular 4x4 CULTURE magazine, exclusive ARB promotional news and new product release information.

23rd March, 2015

SUMMIT BULL BAR

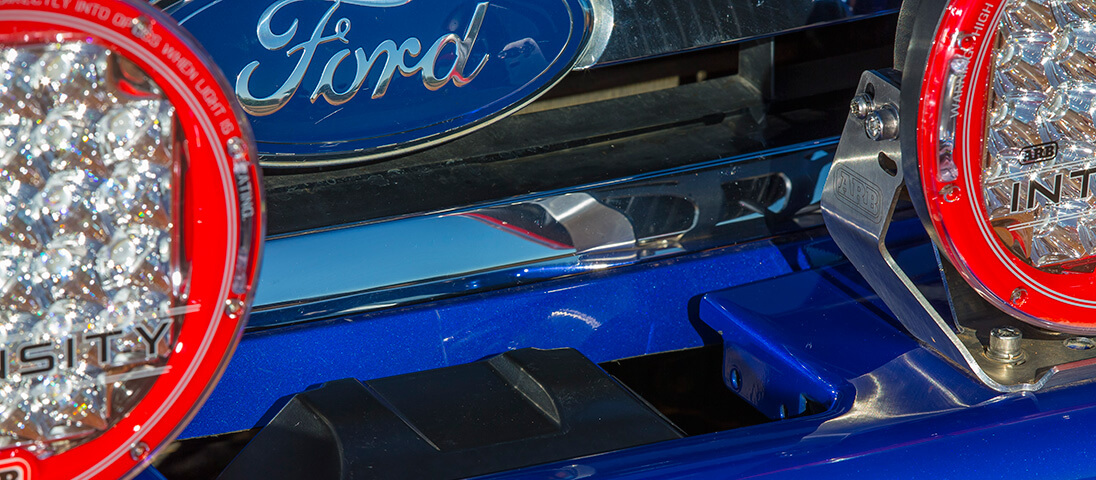

Over the years, ARB has lead the development of frontal protection systems by producing thoughtfully designed and highest quality products on the market. In 2015, this is being taken to new heights with the release of the all new ARB Summit Bull Bar.

Our engineers were tasked with creating a modern interpretation of the renowned ARB Deluxe bar, that would complement modern dual cab and wagon vehicles through a fresh, contemporary design language. The Summit bar builds upon our proven air bag compatible bull bar mounting architecture, while incorporating unique design features such as the 30mm edge radius on the wings and centre pan, wider press formed cover straps, 60.3mm top tubing, two piece polyethylene buffers and redesigned fog light surrounds, to name a few.

A press formed top pan adds strength to the bar, while also allowing for the cover panel to be recessed and fit neatly, should no winch be installed.

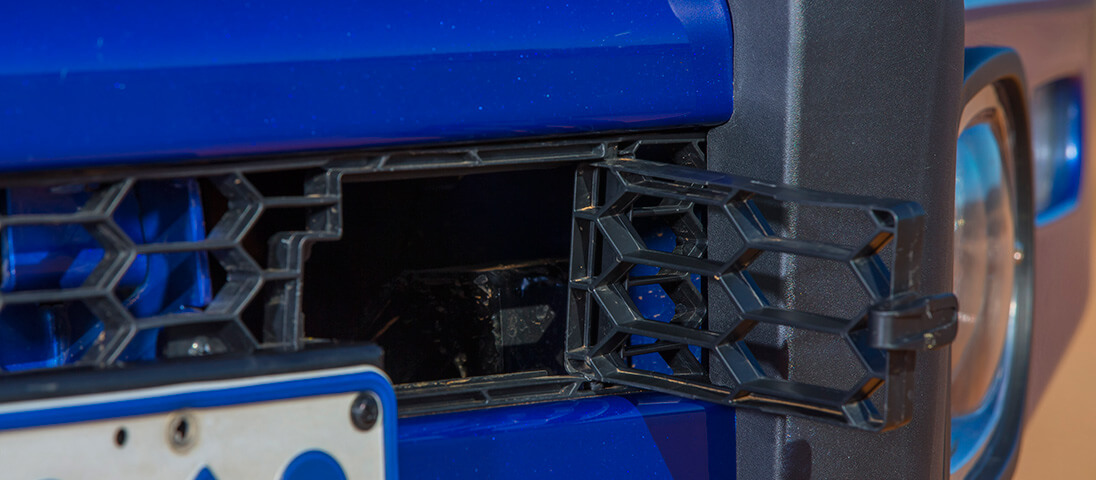

The need for winch clutch cutouts in the top of the bar has been removed, thanks to the wider centre pan. A centre pan grille neatly integrates into the bar, with an access door granting access to allow for easy winch clutch operation.

Summit bars feature ARB’s new fog light surround and accept the ARB 51 watt fog light. A screw in cover plate is supplied as standard for when no fog lights are fitted. A clear fog light cover is also available, offering additional protection against road debris, stones and other foreign matter. LED clearance lights/indicators are installed within a press form aperture in each wing.

The Summit bar accepts a range of Warn, Magnum, Bushranger and Smittybilt winches up to 10,000lbs. Unlike traditional ARB bars where the winch control box is fitted to the top of the centre pan, the Summit bar includes an integrated control box mount to conceal the control box behind the bar and mount it safely away, while further enhancing air flow to the vehicle.

Hi-Lift jack points are located below the buffers and are welded directly to the upright on either side of the bar. This prevents the jack from interfering with the buffer, while providing the strongest possible jacking point.

Adding to the overall visual aesthetics of the Summit bar is the use of synchro pulse controlled welding. The system controls the current pulse so only a single droplet of filler metal is detached each time, resulting in a virtually spatter free weld that offers seam quality in line with that of the TIG process.

SUMMIT SIDE RAILS AND STEPS

Complementing the new bar is the release of the ARB Summit side rails and protection steps. Rather than producing a side rail clamp to suit the increase in tubing diameter on the Summit bar, ARB engineers have developed an integrated, design registered attachment system.

Replacing the traditional checker plate step section is a new extruded, anodised aluminium tread plate. This ridged step section ensures maximum traction when entering and exiting the vehicle in wet or muddy conditions.

The vehicle specific, mandrel formed side rails utilise a larger, 60.3mm steel tubing to provide an increase in strength and visual aesthetics.

Available March 2015, 2011 on Ford Ranger PX models will be the first to receive the ARB Summit bar and side rails lineup, with the range of vehicle applications to expand with time.

Subscribe to ARB to receive your regular 4x4 CULTURE magazine, exclusive ARB promotional news and new product release information.