Subscribe to ARB

Subscribe to ARB to receive your regular 4x4 CULTURE magazine, exclusive ARB promotional news and new product release information.

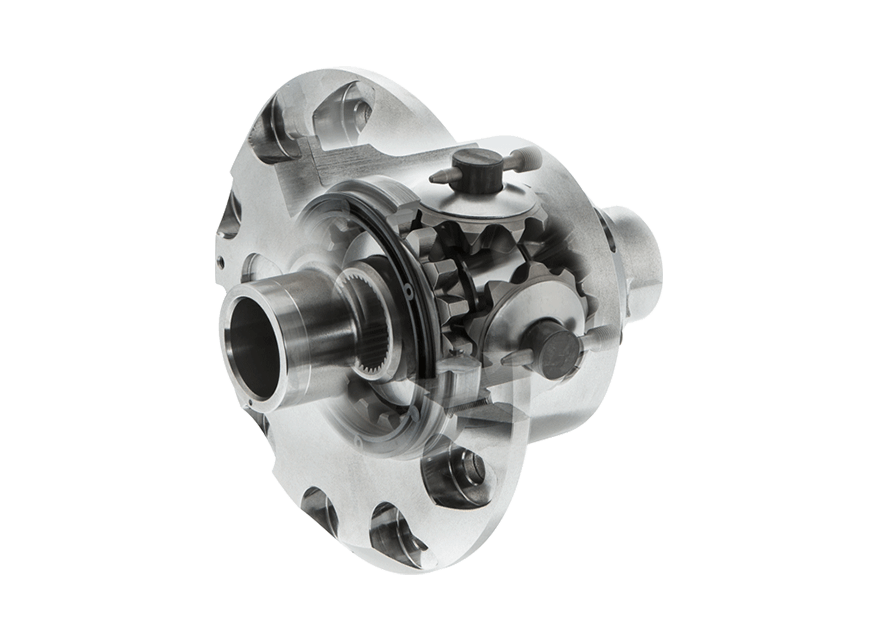

A relentless commitment to research and design, the use of quality materials, and an uncompromising approach to manufacturing have all contributed to the Air Locker’s success in over 100 countries worldwide.

Designed and manufactured in Australia, ARB Air Lockers will enhance the traction of your 4×4 in just about any terrain, whether it’s rock, clay, gravel, sand, snow or mud.

Now with a state-of-the-art two piece design available right across the range, forged gears for the ultimate in strength and durability, and an industry leading five year warranty, ARB Air Lockers are better built and better backed than ever before.

There is a front Air Locker available for your vehicle. * May not apply to all variants, please confirm with your local ARB store or authorised stockist, or download the Air Locker Application Guide below for specific information.

Strength, durability and resistance to fatigue in all Air Locker components is paramount. With phenomenal forces being applied to the side and pinion gears within the differential, ARB has invested heavily in the application of forged gears, typically found in heavy duty commercial, race and agricultural transmissions. When combined with ARB’s patented ‘timed gear’ design, the resulting strength of the whole assembly is amplified.

Housing this superior internal gear train in a two-piece case brings further benefits. Machining a case from two pieces instead of three results in a much higher dimensional accuracy of the finished assembly and has allowed ARB engineers to improve the design of other elements, resulting in a reduction of moving parts, increased strength and a more responsive activation.

For total peace of mind, all ARB Air Lockers are backed by a comprehensive, five year, unlimited kilometre warranty. Coupled with ARB’s extensive domestic and international network of stores and distributors, you can be sure we’ll be there to support you in the unlikely event of an issue.

Fully machined, one-piece nodular iron diff carrier case offers the rigidy of a one-piece factory differential with twice the standard number of pinion gears to cope with the torque.

Fully machined, one-piece nodular iron diff carrier case offers the rigidy of a one-piece factory differential with twice the standard number of pinion gears to cope with the torque.

Fully machined nodular iron flange cap incorporates the stationary side of ARB's tough, proven and patented timed locking mechanism.

High grade surface treatments, forged nickel alloy steel and ARB's patented timed locking system make this the most ‘lockable’ gear in the industry.

Combining the strength of forged nickel alloy steel with redefined gear-tooth geometry, ARB has revolutionised locking differential gear design to yield structural advantages of up to 30% over commercially available high strength gears.

ARB's patented locking system actually supports the side gear teeth, giving you more torque handling capability, exactly when you need it.

A billet machined, alloy steel spider block supports the cross shafts, using the torque applied at each shaft to support the next shaft along.

Alloy steels and performance surface technology make for a high pressure running fit that can handle an enormous amount of punishment.

Custom made, one-piece hardened retaining pins lock into the assembly using a tapered thread junction.

Steel reinforced, elastomer-bonded annular seal has been proven to handle 20,000+ cycles under the most extreme climatic temperatures on earth.

Instead of a complex external actuator system to engage/disengage the lock, ARB Air Lockers use up to 12 return springs to support the entire profile of the locking gear for a fast, positive and independent disengagement.

At the flick of a dash-mounted switch, compressed air is delivered to the seal housing assembly via a nylon air line.

With phenomenal forces being applied to the side and pinion gears within the differential, ARB has invested heavily in the application of forged gears, typically found in heavy duty commercial, race and agricultural transmissions.

Machining a case from two pieces instead of three results in a much higher dimensional accuracy of the finished assembly and has allowed ARB engineers to improve the design of other elements, resulting in a reduction of moving parts, increased strength and a more responsive activation.

Subscribe to ARB to receive your regular 4x4 CULTURE magazine, exclusive ARB promotional news and new product release information.