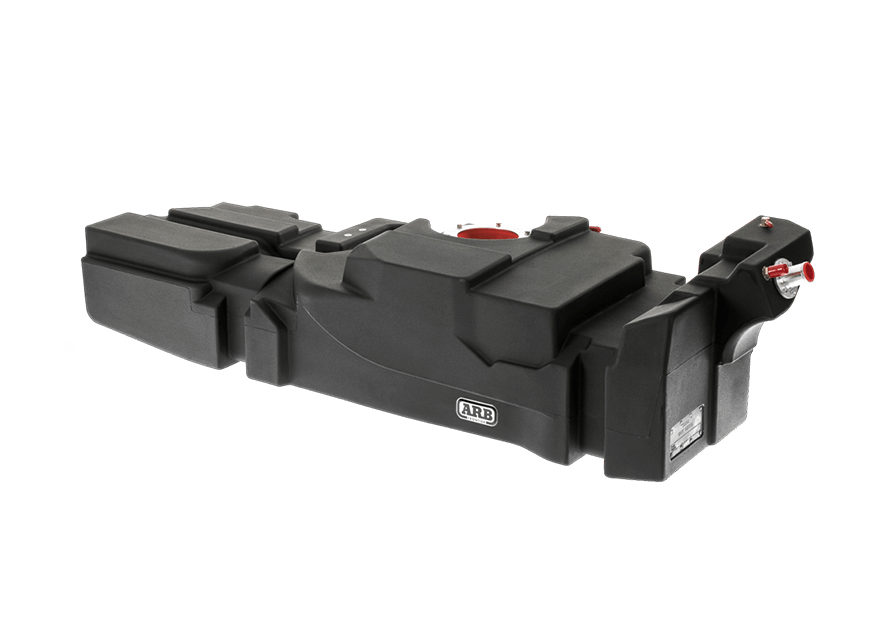

ARB Frontier Long Range Fuel Tank

The all-new ARB Frontier long range tank is setting the benchmark for long range fuel tanks around the world. Manufactured from a resilient cross-linked polymer, each Frontier tank offers incredible strength and rigidity, while providing a significant weight reduction over steel long range tanks. The UV stable plastic material ensures these tanks will survive in the most hostile environments.

With a wall thickness of 7-9mm, every Frontier long range tank is individually pressure tested and backed by an industry-leading three year warranty.

Features

Quality hardware throughout

Each Frontier tank is designed to seamlessly connect to the vehicle's original fill point, allowing for fast, easy fuel delivery. Additionally, the tank breather incorporates a one-way valve to prevent fuel leakage in the event of a vehicle rollover.

Quality hardware throughout

Each Frontier tank is designed to seamlessly connect to the vehicle's original fill point, allowing for fast, easy fuel delivery. Additionally, the tank breather incorporates a one-way valve to prevent fuel leakage in the event of a vehicle rollover.

Designed and tested to go the distance.

Prior to leaving the factory, all Frontier tanks are hydrostatically tested to ensure optimal tank structure and seal integrity.

Vehicle specific fuel pump module

Each fuel pump module sealing flange is CNC machined in order to prevent leakage and eliminate distortion of the mounting area.

One-piece construction

Made from tough, impact resistant plastic polymer, the roto moulding manufacturing process results in no welds or seams in the design, providing exceptional strength and impact resistance.

Vehicle specific design

The use of polymer enables more intricate shapes to be manufactured, ensuring the largest possible volume is achieved for each vehicle application.

Non-rigid mounting system

Rubber coated steel mounting straps allow for movement of the tank within the chassis and have been designed to meet the extra load requirements. They attach to original mounting points within the vehicle chassis, keeping the tank secure and allowing fast and easy installation.

Robust and lightweight

With a wall thickness of between 7mm and 9mm (depending on the model), and less than half the weight of a comparative steel tank, the flexible polymer is resistant to UV, chemicals, fire and heat, as well as providing excellent strength and impact resistance.

Proudly made in Australia by ARB

Includes 3 year warranty

Frontier Tank Torture Test

Manufactured using a state-of-the-art, seamless roto-moulding process, ARB Frontier Tanks are engineered to survive anything you can throw at them off road. Watch as we put one through its paces at Melbourne 4X4’s proving ground.

Frontier Long Range Tank Installation

See first hand how easy and economical ARB Frontier long range tanks are to install.

The roto-moulding process enables designs that feature more intricate shapes to be created, increasing overall tank volume.

Frontier Fuel Tank FAQs

-

Are long range fuel tanks available for both petrol and diesel vehicles?

The Frontier Tank is only appropriate for diesel engines. The cross-link polymer used has a high chemical resistance and is UV stabilised, and is designed specifically to complement diesel fuel.

-

Is the polymer Frontier Tank as strong as a steel tank?

The Frontier Tank is designed for maximum strength, with a durable polymer structure that is much thicker and sturdier than an OE tank. Wall thicknesses in the Frontier Tank are uniformly 8mm, while the corners are around 11mm. This helps to stiffen the tank and make it stronger for a larger carrying capacity. The polymer has the ability to compress and absorb the forces applied, and still return to its original shape, meaning when you run over a log or sizeable rock, even with the entire weight of the car on it the tank can easily absorb the hit.

-

What are the benefits of the wall thickness and thermal properties?

Because plastic as a material possesses more insulation properties than steel, using a plastic tank reduces drastic temperature changes within a fuel tank, even in the High Country or snow conditions. This is beneficial in reducing condensation inside a tank, which commonly occurs when fuel tanks are subjected to drastic temperature changes. Condensation is harmful as it can cause a waxing up of your fuel, lead to an algae bloom, or in a steel tank, cause rust.

-

Are the Frontier Tanks replacement or additional to the OE tank?

All the tanks in ARB’s Frontier Tank range are complete replacements for factory fuel tanks. To install a Frontier Tank the factory tank is removed from the vehicle, then we utilise the original equipment including fuel pumps and pickup senders, and ensure that all the emission features in the original tank are replicated in our tank. Then the fuel sender is dropped into to ARB’s unique mounting flange in the top of the tank, and it operates very similarly to the OE tank.

The Ranger, BT-50 and HiLux all originally possess a capacity of about 80 litres, and with a Frontier Tank we are able to increase that to 140 litres. By keeping the excess fuel under the vehicle, the low centre of gravity can be maintained, even with increased weight.

-

What are the some other key benefits of a Frontier Tank?

The Frontier Tanks possess a range of benefits for drivers.

One benefit is that cross-link polymer is impervious to rust, and all straps and bolts are protected against corrosion, so they will maintain their strength, even in super tough conditions.

Another benefit is the increased chassis flex that a polymer tank can offer. Rubber insulating pads are placed over the surface of the tank where it is mounted to the chassis, as well as on the straps. This allows the tank itself to flex, as well as allowing the chassis to flex, preventing stress on the tank and the chassis. There are no stress or point loads through the mounting brackets or flanges and the like, so stress on the body of the tank is minimised.

The Frontier Tank also provides quite significant weight savings for your vehicle over other alternatives, which helps when keeping within the GVM of your vehicle. The Frontier Tank for a Ford Ranger comes in at about 22 kilograms, whereas a comparative steel one would be up around 50 kilograms. The reduced weight in your fuel tank gives you the ability to add some other accessories to your car.

-

Can I get my fuel gauge to read accurately after fitting a long range fuel tank?

As there is a significant increase in fuel, some of it will sit above the sender line. For this reason, on each tank of fuel the fuel gauge will remain on full for a longer time than with the OE tank. At the lower end of the gauge however the reading becomes very accurate. The fuel light and lower-end reading will be as before with the OE tank, meaning no unpleasant surprises. We would encourage new Frontier Tank users to test their tanks with a few full runs of fuel, to become comfortable with the characteristics of the fuel gauge.

-

What should I do if the tank is contaminated?

Contaminated fuel can lead to some serious issues for your car, including engine failure. In the event of fuel contamination, the best thing to do is to remove the tank immediately and thoroughly clean it.

With the absence of baffles and the inclusion of a large opening at the top, it is relatively easy to thoroughly cleanse the inside of the tank, and it is absolutely essential. You can clean the tank yourself so long as it is done thoroughly, using CRC Multi-Purpose Spray or WD-40 spray, and a clean, dry rag.

-

Where are ARB Frontier Tanks made?

Frontier Tanks are entirely manufactured by ARB in-house, in Australia. The mounting hardware is made in Melbourne, and the tanks are made in South Australia. We’re proud to say this is a 100% Australian made quality product we are offering.

-

Why don’t Frontier Tanks have baffles?

The traditional function of baffles is to slow the movement of fuel through the tank, but the inclusion of a swirl pot in the Frontier Tank reduces the need for baffles. The swirl pot maintains a head of fuel constantly available at the pickup instead. By not including baffles, the cleaning process is also made easier. Without the inclusion of baffles, the interior surface is significantly easier to wipe down.

-

Why don’t Frontier Tanks have a drain plug?

There are a number of reasons for excluding a drain plug on our Frontier Tanks. One major benefit to excluding a drain plug is maintaining the structural integrity of the tank. With a moulded tank there is the ability to keep the product as a single, seamless structure, providing the tank with maximum strength and integrity, even in challenging situations which place stress on the tank. A drain would provide a point of weakness on the footprint of the tank, compromising strength.

Due to the nature of drainage plugs, the placement would compulsorily be the lowest point of the tank. This would require the tank to slope down to its weakest point, which would possibly jeopardise the indestructibility of the tank by causing a weakness at the most vulnerable point, where there is the greatest chance of snagging on an unseen rock or log.

A further reason the ARB Frontier Tank has been produced without a drainage plug relates to the cleaning process. Unfortunately a contaminated tank poses significant risk to the health of a vehicle. Simply letting out fuel in most instances would not be sufficient to clear the contamination. The tank would need to be removed in any case for adequate cleaning, meaning the value of the drainage plug would not be substantial, and, would likely not outweigh the structural drawbacks.

You may also be interested in

Subscribe to ARB to receive your regular 4x4 CULTURE magazine, exclusive ARB promotional news and new product release information.